Understanding the Capillary Viscometer

Capillary viscometers are precise instruments used to measure the viscosity of a fluid. They work by observing the time it takes for a liquid to flow through a narrow tube under the influence of gravity. Widely employed in numerous industries, these devices aid in the quality control and research of various substances, from oils to polymers.

Introduction to Viscosity Measurement

The field of fluid dynamics heavily relies on accurate viscosity measurements, and the capillary viscometer is a staple tool in this area. Understanding the flow properties of fluids is crucial across industries, from pharmaceuticals to petroleum. Viscosity, a fluid’s resistance to deformation or flow, plays a key role in determining how a fluid behaves under various conditions. The measurement of viscosity is significant not just for product formulation but also for regulatory compliance, safety, and innovation in product development. Thus, a precise measurement helps in formulating products that meet stringent quality standards while also ensuring compliance with industry regulations.

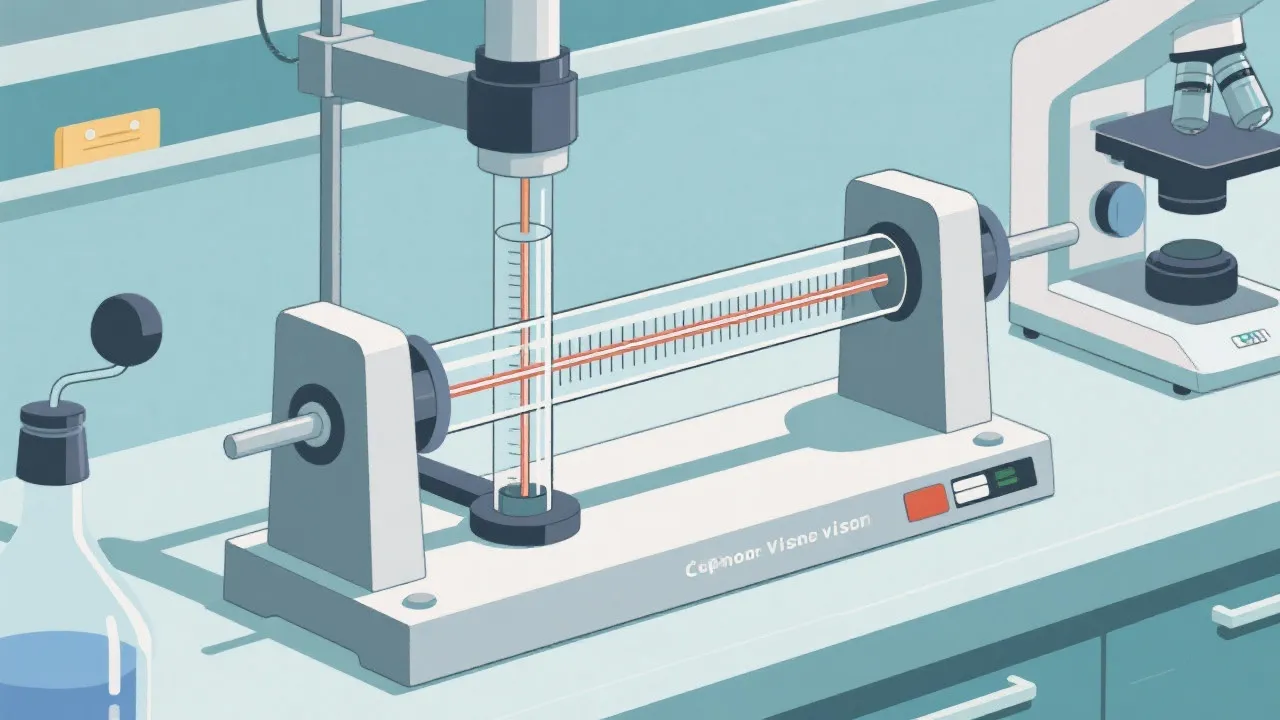

How Does a Capillary Viscometer Work?

A capillary viscometer measures viscosity based on the principle of laminar flow through a narrow tube or capillary. When a fluid is allowed to flow through this tube, its viscosity can be calculated by timing how long it takes for the fluid to travel a certain distance. The duration, typically measured in seconds, indicates the fluid's viscosity: longer flow times indicate higher viscosity. The relationship between flow time and viscosity is often defined by the Poiseuille’s equation, which relates viscosity to the physical properties of the fluid and the dimensions of the capillary tube.

In practice, two primary types of capillary viscometers are frequently utilized: U-tube viscometers and Ubbelohde viscometers. The U-tube viscometer, which allows the liquid to flow under the influence of gravity, contains two arms that can help measure the height difference caused by fluid motion—a correlation that can be used to calculate viscosity. On the other hand, the Ubbelohde viscometer is designed to minimize errors caused by temperature fluctuations and surface tension, thus providing greater accuracy. These viscometers are essential in settings where small sample volumes are available, ensuring efficiency alongside precision.

Significance in Various Industries

Capillary viscometers find applications in a multitude of industries, each with unique viscosity measurement needs. In the automotive industry, capillary viscometers are crucial for analyzing engine oils and lubricants, ensuring optimal performance and longevity of engines. The viscosity of lubricants can affect fuel efficiency and engine wear, hence keeping viscosity within specified limits is vital for operational efficiency and vehicle lifespan.

Similarly, in the pharmaceutical industry, capillary viscometers play a crucial role in maintaining the quality and consistency of medicinal syrups and suspensions. Viscosity measurements help ensure that dosages remain uniform and that products will be stable throughout their shelf life. In the cosmetics industry, such viscometers aid in quality control for creams, lotions, and gels, where texture consistency is vital for consumer satisfaction. The viscosity of these products can affect their application, stability, and overall effectiveness.

Furthermore, in the food industry, capillary viscometers are critical in determining the consistency of viscous products like sauces, gravies, and dressings. Accurate viscosity measurement directly influences product formulation, quality assurance, and labeling standards. This is important not only for consumer satisfaction but also for meeting regulatory requirements that dictate the characteristics of food products, ensuring they are safe and effective for consumption.

| Industry | Application |

|---|---|

| Automotive | Analyzing and formulating lubricants for engines. |

| Pharmaceutical | Ensuring the consistency and stability of medicinal syrups. |

| Cosmetics | Quality control in creams and lotions for texture consistency. |

| Food | Consistency measurements in viscous products like condiments. |

| Petroleum | Characterizing crude oils and refined products for processing. |

| Chemical | Determining viscosity of various formulations and solutions. |

| Textile | Measuring viscosity of dyes and finishing agents. |

| Paint and Coatings | Ensuring proper application characteristics of paints and coatings. |

| Adhesives | Testing the viscosity for optimal application and bonding. |

Purchasing Capillary Viscometers: Factors to Consider

When acquiring a capillary viscometer, several factors should be considered to ensure you select the right instrument for your needs. Firstly, understanding the intended application is paramount; knowing whether the viscometer will be used for routine quality control or for more specialized research can influence the choice of model and specifications. For example, if high accuracy is required, more advanced models might be necessary.

The viscosity range of fluids to be tested is another crucial consideration. Different viscometers are rated for different viscosity ranges, and choosing an instrument that accommodates your fluids can prevent inaccuracies and inefficiencies. In addition, the required precision must be assessed; some applications, such as pharmaceutical testing, may necessitate more precise instruments, while others might tolerate greater variability.

It is also essential to source from reputable suppliers who not only sell quality equipment but also offer robust customer service and technical support. Companies that provide training on instrument usage and maintenance are invaluable resources. Lastly, reviewing certifications and compliance with industry standards ensures the selected device meets necessary regulations and offers reliable measurements.

Advantages and Limitations

The capillary viscometer is favored across different sectors for its simplicity and relatively low cost compared to other viscometry methods, such as rotational viscometers. It provides a straightforward way to achieve reliable viscosity readings without the need for complex equipment setups. Furthermore, due to their design, capillary viscometers often require smaller sample volumes, making them ideal for scenarios where sample availability is limited.

However, there are limitations to consider. One significant drawback is temperature sensitivity; viscosity measurements can change dramatically with temperature fluctuations. Hence, it is crucial to perform measurements under controlled temperature conditions and calibrate the devices accordingly. Additionally, capillary viscometers struggle with non-Newtonian fluids—those whose viscosity changes with the rate of flow—requiring more advanced viscometer designs or calculations and additional considerations for accurate results. For instance, shear-thinning or shear-thickening fluids may not provide reliable data using traditional capillary methods alone.

FAQs

- What is a capillary viscometer? A device used to measure the viscosity of a liquid by observing its flow through a thin tube.

- What industries use capillary viscometers? They are widely used in industries such as automotive, pharmaceutical, cosmetics, food, petroleum, and chemicals.

- What should I consider when buying a capillary viscometer? Consider factors like the fluid's viscosity range, intended application, required precision, and supplier reliability.

- What are the advantages of using a capillary viscometer? They are simple to use, cost-effective, require less sample volume, and provide reliable viscosity measurements for many applications.

- Are there any limitations? Yes, they may encounter difficulties with non-Newtonian fluids and are sensitive to temperature variations that can affect results.

Conclusion: The Importance of Capillary Viscometers in Fluid Dynamics

In conclusion, while capillary viscometers are invaluable tools for measuring fluid viscosity, understanding their operation, the industries they serve, and the considerations for their purchase can significantly enhance their application in your field. The ability to accurately measure viscosity is crucial in ensuring that products are effective, safe, and compliant with regulatory standards. Whether for research or product development, these instruments are indispensable in ensuring product quality and performance. Investing in the right capillary viscometer, equipped with the necessary support and service, can lead to better outcomes in product formulation, quality assurance, and overall operational efficiency. As industries continue to evolve and demand more precise measurements, the role of capillary viscometers will remain central in driving innovation and excellence.

Future Trends and Innovations in Viscosity Measurement

As technology continues to advance, the methodology for measuring viscosity is also evolving. New innovations in digital viscometers and sophisticated software are paving the way for more precise and automated measurements. For example, the integration of microfluidics technology enables extremely small sample volumes and real-time viscosity monitoring, which is particularly beneficial in research environments.

Moreover, predictive modeling using artificial intelligence (AI) and machine learning (ML) is beginning to enter the realm of viscosity measurement. These techniques can analyze vast amounts of data to predict how fluids will behave under varying conditions, significantly enhancing the efficiency and accuracy of viscosity testing. AI can optimize the calibration processes of viscometers, autonomously adjusting settings to improve consistency across measurements.

Additionally, the development of portable viscometers and smartphone-compatible devices is increasing accessibility for individuals in the field. This allows for on-site viscosity measurements without the need for extensive laboratory setups, promoting real-time quality control in various industries.

As companies place greater emphasis on sustainability and eco-friendliness, viscous material formulations are also adapting to use more environmentally friendly components without compromising performance. Viscosity measurement will continue to play a critical role in ensuring that these new formulations maintain desired characteristics.

In summary, ongoing advancements in viscosity measurement technology will enhance accuracy, efficiency, and applicability across a growing number of fields, reaffirming the role of capillary viscometers as essential tools in the ever-evolving landscape of fluid dynamics.