Mastering Capillary Viscometers

Capillary viscometers are essential devices used in various industries to measure the viscosity of fluids. These instruments rely on the principle of fluid flow through a capillary tube, giving insights into a fluid's resistance to deformation. Understanding their operation and application is crucial for professionals in research, manufacturing, and quality control. This article delves into the technicalities, advantages, and applications of capillary viscometers.

The Science Behind Capillary Viscometers

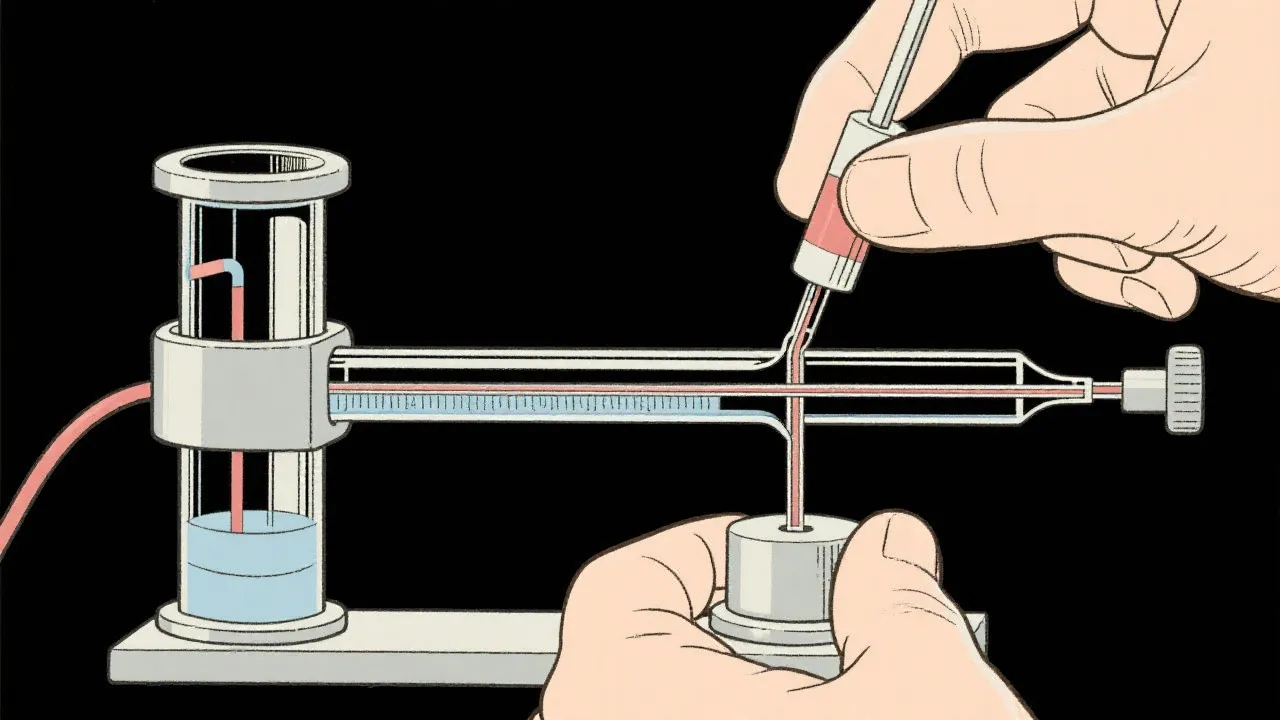

Capillary viscometers are precision instruments designed to measure the viscosity of fluids. This critical parameter helps in understanding a fluid’s resistance to flow, an essential factor in numerous industrial processes and scientific research. The device operates by analyzing the time taken for a fluid to pass through a narrow tube under the influence of gravity or external pressure. This time measurement translates to the fluid's viscosity using specific equations related to capillary flow dynamics. The fundamental principle behind capillary viscometers is based on the behavior of fluids in constellations defined by the segments of tubes, which makes them especially interesting from a theoretical standpoint. This underlines not just the operational mechanics of viscometers but also their relevance in modern science where fluid dynamics plays a pivotal role.

Technical Overview

The capillary viscometer functions on the Hagen-Poiseuille equation, which describes the flow of incompressible fluids in a cylindrical tube. According to this equation, the viscosity (\(\eta\)) of a fluid is directly proportional to the pressure difference (\(\Delta P\)) across the length of the tube and inversely proportional to the fourth power of the radius of the tube (r), and the length of the tube (L). The formula can be expressed mathematically as:

\[ \eta = \frac{8L}{\pi r^4} \times \frac{\Delta P}{v} \]

Where v is the flow rate of the fluid. The implications of this relationship highlight the delicate balance between various physical dimensions of the tube and the properties of the fluid itself. As such, the Hagen-Poiseuille equation provides a crucial framework for understanding fluid flow in capillary tubes. Though seemingly straightforward, precise calibration and handling are paramount for accurate readings. This importance magnifies when one considers factors such as temperature, which can significantly affect viscosity, and thus necessitates careful thermal management during measurements. The expertise of operators is vital in industries like petrochemicals, pharmaceuticals, and foods, where even slight variances in viscosity can lead to substantial operational challenges.

Key Advantages

Among the numerous benefits of using capillary viscometers are their simplicity and high accuracy. They generally do not involve complex mechanical systems and thus require minimal technical expertise for operation, ensuring easily repeatable experiments. Furthermore, they can handle a wide range of fluid viscosities, making them adaptable for diverse industrial applications, from low-viscosity solvents to high-viscosity oils. Their ability to function without any moving parts considerably reduces maintenance stresses and long-term operational costs. However, regular maintenance is critical to prevent blockages in the capillary tube, which can skew results and damage the instrument. This highlights the necessity of scheduled checks and balances within an industrial setting, wherein not just the viscosity measurement process itself but also its supporting infrastructure is kept in top operational condition.

Another notable advantage is their effectiveness in generating reproducible results, making capillary viscometers a preferred choice in research environments where experimental consistency is paramount. The straightforward nature of capillary viscometers also facilitates their integration into sophisticated laboratory setups, along with being compatible with computer interfaces for data analysis. The ability to capture and analyze data digitally can greatly enhance the user experience and increase analytical accuracy, particularly in high-throughput settings.

Applications Across Industries

Capillary viscometers find widespread use in industries where fluid behavior is crucial. In chemical manufacturing, for instance, understanding viscosity ensures the correct composition and behavior of products like adhesives, inks, and coatings. Each of these products has particular viscosity requirements that must be meticulously controlled to ensure optimal performance. In the food industry, capillary viscometers play a vital role in maintaining product consistency and quality for items such as sauces, syrups, and dressings, which rely on specific texture and flow properties as dictated by viscosity.

In pharmaceuticals, the reliance on viscosity measurements extends to the formulation of liquid medications, where ensuring the stability and efficacy of these drugs is directly correlated with their fluid properties. Many pharmaceutical products need to maintain a certain viscosity to ensure proper delivery mechanisms, which involves diverse processes from manufacturing to the point of consumption. A noteworthy instance would be in the preparation of suspensions, where properly measuring and adjusting viscosity is essential for ensuring that the active ingredients are evenly dispersed throughout the fluid.

Moreover, capillary viscometers have found significant applications in petroleum industries, where they are used to characterize crude oil and its derivatives. The viscosity of petroleum products is required for many calculations, including but not limited to pipeline transportation and combustion characteristics. Fuel oils, lubricants, and even biodiesel are regularly assessed using capillary viscometers to ensure compliance with industry standards and to optimize performance in real-world applications.

In the cosmetic industry, where formulations often entail complex interactions between different ingredients, capillary viscometers help ensure that lotions, creams, and emulsions maintain the desired texture and performance throughout their shelf lives. This phenomenon reveals the interconnectedness of various segments of the economy, emphasizing how viscosity control supports not just aesthetic preferences but product stability as well. Each industry not only requires precise measurements but also sees advancements in technology enabling better viscosity control and assessment, iterating the relevance of capillary viscometers across sectors.

FAQs About Capillary Viscometers

- How do capillary viscometers maintain accuracy?

Regular calibrations using standard fluids are essential, alongside periodic cleaning to prevent tube blockage. Calibration procedures are typically performed using reference fluids of known viscosities. This ensures the viscometer remains accurately aligned with established standards, enabling consistent and accurate measurements. Furthermore, maintaining stable temperature conditions during viscosity measurements is crucial, as even small temperature fluctuations can lead to significant deviations in viscosity readings. Many advanced viscometers offer integrated temperature control systems for this very reason. - Can they measure non-Newtonian fluids?

Capillary viscometers are primarily optimized for Newtonian fluids, which exhibit consistent viscosity regardless of the applied shear rate. For non-Newtonian fluids, which display variable viscosity based on shear stress or rate, alternative methods such as rotational viscometers or ultrasonic viscometers are often preferred. However, researchers are continually exploring ways to adapt capillary viscometer designs to provide more accurate measurements for non-Newtonian behavior, though this remains an area that lacks standardization. - What are common errors in measurement?

Incorrect temperature control, inadequate calibration, and improper use of viscosity standards are frequent sources of discrepancies in measurements. In addition, the handling technique while filling the capillary tube can influence results; techniques such as bubble-free filling are crucial to avoid trapping air, which can affect results. Moreover, the viscosity of the fluid may be influenced by its chemical composition, so it is critical to use the appropriate characterization technique for each specific application to mitigate measurement errors.

Conclusion: The Importance of Capillary Viscometers

Capillary viscometers play a crucial role in the precise measurement of fluid viscosity, benefitting numerous sectors by ensuring product quality and process efficiency. Mastery in their use and maintenance can significantly enhance the outcomes of various industrial operations, leading to increased productivity and reduced waste. As technology advances, these instruments continue to evolve, offering more sophisticated methods to evaluate fluid dynamics with increased precision and versatility. For instance, recent innovations include digital capillary viscometers that not only automate the measurement process but also provide advanced data logging capabilities, enabling enhanced analysis and improved quality control. The future of capillary viscometry appears bright, with ongoing research promising to address existing limitations and extend its applications into newer fields such as biopharmaceuticals and nanotechnology. Hence, capillary viscometers remain an indispensable tool in modern science and industry, supporting innovations across diverse sectors.

The Role of Viscosity in Fluid Dynamics

Understanding viscosity is fundamentally essential for tackling fluid dynamics challenges. Viscosity not only defines how fluids behave under different conditions, but it also influences various real-world phenomena, such as the mixing of fluids, heat transfer, and even the behavior of biological systems. For example, in aerodynamics and hydrodynamics, viscosity plays a critical role in determining drag forces acting on objects moving through fluids. This makes viscosity a key factor for engineers designing vehicles and structures intended to minimize resistance and maximize efficiency.

In natural systems, viscosity is a major determinant of nutrient transport in bodies of water, affecting how ecosystems function and how organisms thrive. Insights related to fluid dynamics, infused with viscosity measurements, empower scientists to model environmental changes accurately, be it predicting weather patterns or assessing the impacts of climate change on ocean currents. Furthermore, in biomedical applications, knowledge of cytokine viscosities has implications on cellular interactions and overall health. The consequence of viscosity extends beyond mere fluid flow theories; it has profound implications across multiple scientific disciplines, interlinking fluid behavior with broader ecological, industrial, and medical phenomena.

Emerging Technologies in Viscosity Measurement

The advancement of technology has ushered in promising trends and innovations, expanding the landscape of viscosity measurement tools. Researchers are exploring various technologies to address the challenges of measuring complex fluids with high accuracy and precision. Ultrasonic viscometers, for example, are starting to gain traction for their ability to characterize fluid properties without consistent reliance on traditional physical parameters like pressure and vorticity. By employing sound waves, they allow for non-invasive viscosity measurements, making them suitable for sensitive applications like food safety and biomedical diagnostics.

Moreover, microfluidic technologies are revolutionizing viscosity measurements by enabling high-throughput analysis. They facilitate the examination of minute fluid volumes under controlled conditions, applying concepts from capillary viscometry at micro-levels. The innovations in this sector hold potential for personalized medicine, cosmetics formulations, and even rapid testing protocols in industrial production lines. The integration of artificial intelligence (AI) into viscosity measurement systems is another emerging trend, where machine learning algorithms can optimize measurement processes, analyze complex viscosity data, and provide predictive insights for future performance. Such advancements herald a new epoch in fluid dynamics studies, fostering innovation across various industries.

The Future of Capillary Viscometers

Looking ahead, the future of capillary viscometers seems promising as they evolve with technological advancements. Innovations are poised to make these instruments even more reliable, cost-effective, and user-friendly. The development of software applications that can simulate fluid behavior under various conditions through real-time data integration was previously unimaginable. This can significantly boost the ease of extrapolating viscosity in untested scenarios, thereby providing a basis for better product formulation across a multitude of industries.

Additionally, with environmental regulations becoming increasingly stringent, the need to ensure that all manufacturing processes meet sustainability standards is paramount. Capillary viscometers can be integrated with systems that monitor environmental impacts, contributing invaluable data to manufacturers looking to minimize waste or optimize resource use. Their portability and ability to present precise viscosity measurements in real-time suit on-the-go applications, thus promoting field measurements without compromising analytical integrity. This adaptability signifies their potential to become standard tools not only in laboratories but also across various aspects of fieldwork, enhancing the interplay between theoretical understanding and practical application.

As markets continue to evolve, the role of capillary viscometers will undoubtedly expand, inspired by the growing interconnectivity of global supply chains and the vast array of emerging applications. Ultimately, the sustained development and adaptation of capillary viscometers will serve as a cornerstone for further understanding in fluid dynamics, ensuring that industries and researchers alike can uphold performance and innovation.