Understanding the Capillary Viscometer

Capillary viscometers are essential devices in the scientific realm, particularly for their role in measuring the viscosity of fluids. These instruments provide accurate and reliable data required for various industrial applications, including quality control in the manufacturing of oils and polymers. Their design enables the precise calculation of fluid dynamics, making them indispensable in both research and industrial settings.

Introduction to Capillary Viscometers

Viscosity is a critical property of fluids that defines their resistance to deformation or flow. A capillary viscometer is a device used to determine this property, providing precise measurements necessary in both scientific research and industrial applications. The tool's design leverages the principles of capillary action, where a fluid's flow rate through a narrow tube is used to calculate its viscosity. This introductory guide will explore various aspects of capillary viscometers, shedding light on their construction, function, and real-world applicability.

The Functionality of Capillary Viscometers

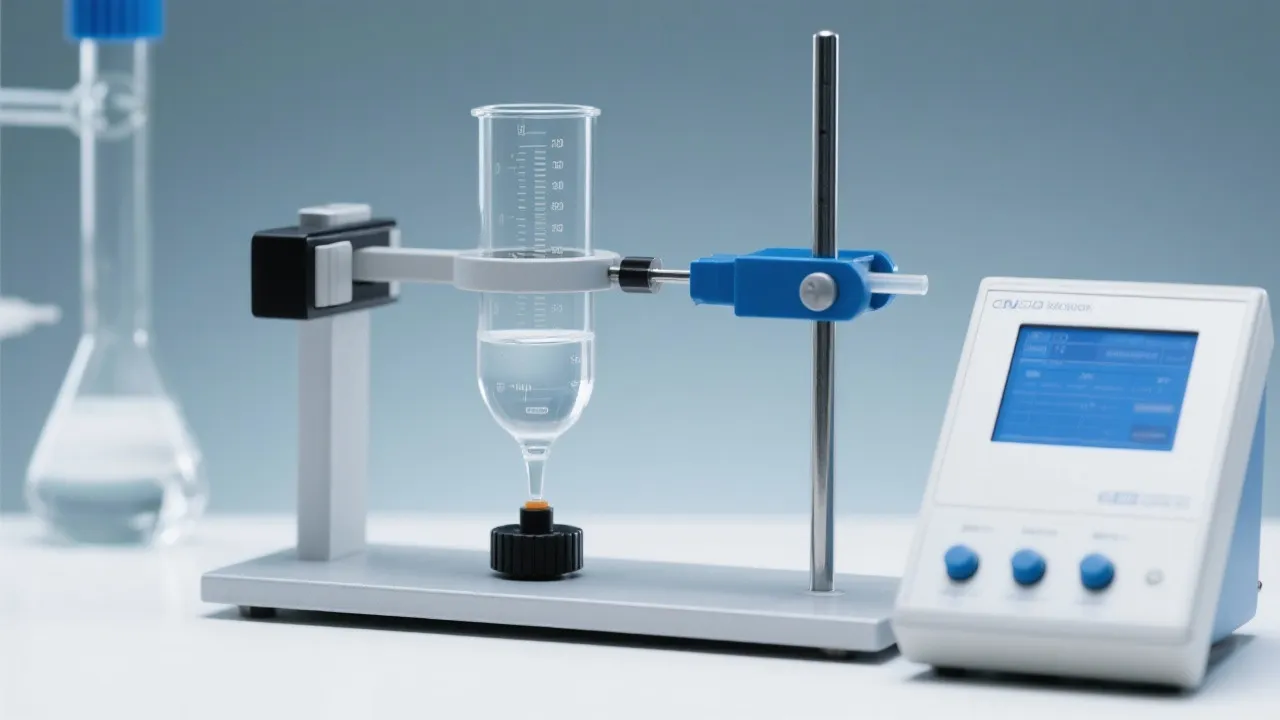

Capillary viscometers operate on the principle that the time it takes for a specific volume of liquid to pass through a tiny capillary tube is directly related to its viscosity. This measurement is generally conducted under thermal equilibrium to ensure the highest accuracy. Temperature-controlled baths often accompany these devices to maintain consistent conditions throughout the testing phase, thus ensuring that data remains valid and reproducible across different conditions. The relationship between viscosity and the flow rate in capillary tubes is explained by Poiseuille's law, which relates to the laminar flow of fluids through conduits.

In practice, a fluid is introduced into the viscometer and allowed to flow from one reservoir to another through the capillary tube. The time taken for the fluid to flow between two marked points on the tube is recorded. The viscosity is then calculated using the dimensions of the capillary, the density of the liquid, and the time measurement, allowing for an accurate representation of the fluid’s rheological properties.

Design and Components

The design of a capillary viscometer is elegantly simple yet highly effective. It consists of a U-shaped tube, which is usually made from glass due to its transparency and chemical inertness. Each arm of the U contains a bulb; one holds the fluid sample, while the other serves as a measuring tube through which the fluid flows under the influence of gravity. These viscometers are often available with various capillary tube sizes, allowing for measurements across different viscosity ranges.

The capillary itself is typically a precise, narrow tube, and its diameter is crucial; a smaller diameter increases the resistance the fluid faces, which can yield readings that are sensitive to minute changes in viscosity. Many viscometers are designed with a specific calibration, ensuring that they provide accurate results only for the types of fluids they were designed to measure, often including a set of guidelines for the preferred sample conditions for best results. The physical design often incorporates various features that make handling and reading easier, such as graduated scales or sight glasses for monitoring the fluid levels.

Applications in Industry

Capillary viscometers are employed in numerous industrial sectors, including the petrochemical, pharmaceutical, and food industries. They are instrumental in quality control processes, where the viscosity of raw materials, intermediates, and final product formulations must be meticulously monitored. In the realm of polymers, for instance, the flow characteristics derived from viscosity measurements can indicate molecular weight and distribution, critical parameters in ensuring product quality and performance.

In the petrochemical sector, for example, accurate viscosity measurements can dictate the efficiency of processes such as refining, as they affect fluid transport and processing operations. Similarly, the pharmaceutical industry relies heavily on viscosity to ensure the consistency of drug formulations, particularly in liquid medicines, where uniformity is paramount for efficacy and safety. In food production, viscosity testing can influence product texture and mouthfeel, directly impacting consumer satisfaction.

Capillary viscometers are also crucial in the development and testing of new materials. From assessing the properties of paints and coatings to determining the viscosity of inks and adhesives, these tools provide essential data for product development and quality assurance across a broad spectrum of applications. Their reliability and precision make them invaluable to researchers and product developers who need to ensure uniformity and compliance with regulatory standards.

Types of Capillary Viscometers

| Type | Description |

|---|---|

| Ostwald Viscometer | Simple to use for Newtonian fluids, measures the time taken for a set volume of fluid to pass between two marked points within a capillary tube. |

| Ubbelohde Viscometer | Ideal for determining kinematic viscosity, where the measurement is independent of the volume of the liquid sample. |

| Cannon-Fenske Viscometer | Well-suited for transparent and opaque liquids and provides enhanced reliability by combining both kinematic and dynamic viscosity measurements. |

Besides these, there are also specialized capillary viscometers designed for specific applications, such as the Sutherland viscometer, which measures the viscosity of gases. It's important to choose the correct type based on the fluid characteristics and the necessary precision. Each of these viscometer types comes with specific protocols for use and calibration, ensuring accurate viscosity measurement across various fluid types.

Advancements and Innovations

Recent advances in viscometer technology include electronic sensing and data logging capabilities, which facilitate better integration into automated systems and data management workflows. These innovations enhance the precision of measurements and streamline the analysis processes, offering a significant leap forward in efficiency and accuracy. Additionally, the development of viscometers capable of handling non-Newtonian fluids expands the range of applicable fluids, from simple liquids to complex slurries and pastes.

Modern viscometers often utilize microprocessors to automate the measurement process. They can record the data in real time, allowing for immediate analysis and reducing the likelihood of human error. Wireless technology also means that measurements can be taken in remote locations or integrated seamlessly into existing process control systems. The ability to measure under conditions of varying shear rates opens new avenues in research and testing, especially for materials that behave differently under fluctuations in stress.

Moreover, the development of software tools for the interpretation of viscosity data is revolutionizing how industries analyze flow properties. Advanced algorithms and computational models can simulate fluid behavior, helping scientists and engineers predict how new formulations will perform in actual use, thereby saving both time and resources in product development.

Finally, the rise of 3D printing technologies is inspiring innovations in viscometer design. Customizable apparatus can now be designed to meet the unique needs of specific applications, allowing researchers and industries to acquire tailored viscosity measurement tools that suit their specific requirements effectively.

FAQs

- What is the primary use of a capillary viscometer?

A capillary viscometer is mainly used to measure the viscosity of fluids, a vital parameter in quality control and research across various industries. - How does temperature affect measurements?

Temperature can significantly impact the viscosity of fluids, so it is often controlled during experiments to ensure accurate readings. - What industries primarily use capillary viscometers?

Industries such as petrochemical, pharmaceutical, and food production utilize these instruments for quality control and research purposes. - What is the difference between Newtonian and non-Newtonian fluids?

Newtonian fluids have a constant viscosity irrespective of the applied shear rate, while non-Newtonian fluids can change viscosity under varying shear conditions. - What is the calibration process for a capillary viscometer?

Calibration typically involves using standards of known viscosity to ensure that the measurements obtained by the viscometer are accurate. This process often requires multiple reference points and can differ based on the type of viscometer used. - How can the results from a capillary viscometer influence product formulation?

The viscosity measurements obtained can help formulators adjust ratios of ingredients, ensuring products meet desired performance characteristics, such as flow rates, stability, and texture. - Are capillary viscometers suitable for all types of fluids?

While capillary viscometers are versatile, their effectiveness can vary with fluid characteristics. High-viscosity fluids, for instance, may require specialized viscometers to accurately measure viscosity.

Conclusion

The role of capillary viscometers in scientific and industrial environments cannot be overstated. By facilitating precise measurements of fluid viscosity, these devices ensure the quality and consistency of products across several fields. Their straightforward design, combined with ongoing technological innovations, underscores their importance and continued relevance in modern research and industrial applications. Researchers and industry professionals alike depend on these instruments to provide accurate and reliable data, underscoring the capillary viscometer's ongoing value and utility.

Looking ahead, the evolution of capillary viscometers appears promising. As innovation continues to reshape how we understand and measure fluid behavior, the capillary viscometer will likely evolve to meet new challenges in measuring complex fluid dynamics. Education and training in the use of this technology will also be vital as it becomes increasingly integrated into the workflows of varied industries.

The future of viscosity measurement holds exciting prospects with advancements in materials science, sensor capabilities, and data analytics. These developments will not only enhance the capabilities of professionals in the field but also lead to more accurate and robust methodologies for characterizing fluids across a multitude of applications—from industrial processes involving heavy oils to cutting-edge research in biomedical applications. As industries continue to demand higher quality and performance from their products, the ongoing refinement and adoption of capillary viscometers promise to play an integral role in achieving these goals.