Understanding Bamhi Thermo Technology

Bamhi Thermo represents a cutting-edge advancement in thermal technology, playing a crucial role in various industrial applications. This innovative solution utilizes advanced materials and design to enhance thermal management across multiple sectors. It is vital for industries seeking efficient and effective temperature control solutions. Dive deeper into the mechanics and applications of Bamhi Thermo technology.

Introduction to Bamhi Thermo

Bamhi Thermo stands at the forefront of thermal management solutions, offering a pivotal technology that transforms the way industries manage heat and temperature. Designed to cater to a wide range of applications, Bamhi Thermo enhances efficiency and efficacy, providing industries with the tools necessary to tackle thermal challenges. Notably, the technology is engineered not just for performance, but with a keen eye on sustainability and reducing the ecological footprint of thermal processes. This introduction to Bamhi Thermo sets the foundation for understanding its impact across various sectors.

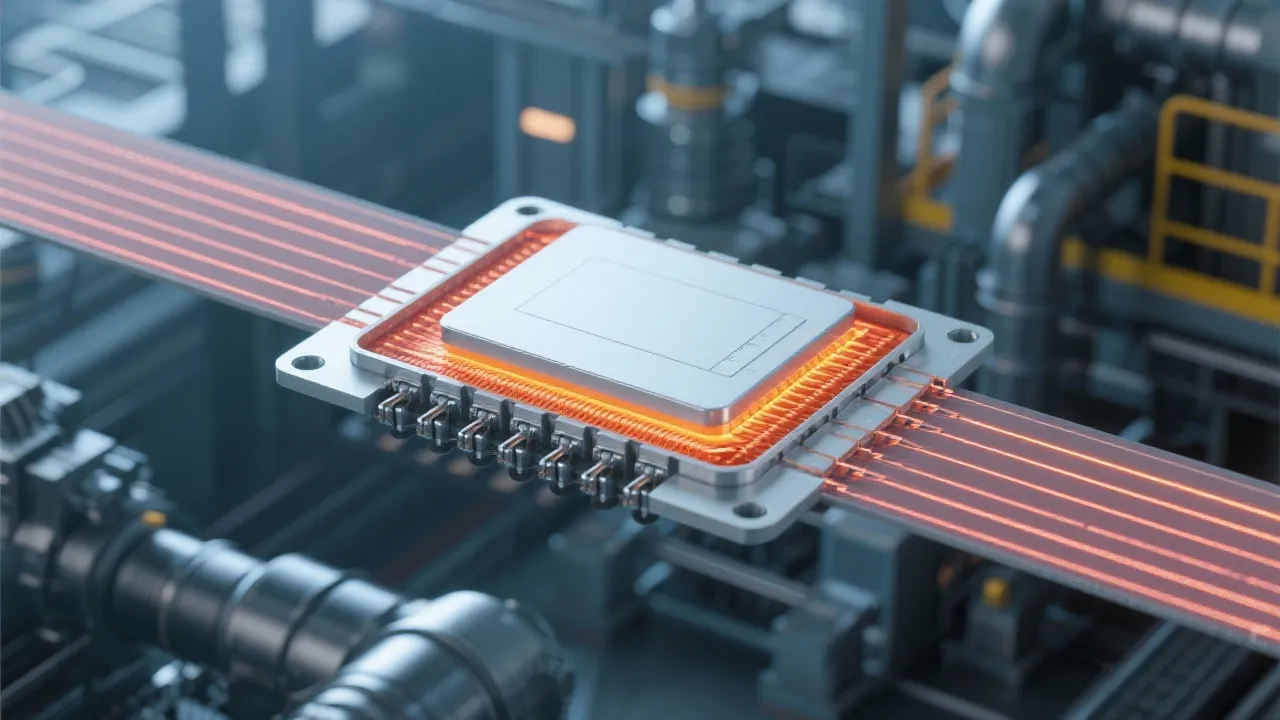

The Technology Behind Bamhi Thermo

At the core of Bamhi Thermo technology is its sophisticated use of materials designed to optimize thermal conductivity while maintaining structural integrity. This involves a careful selection of composites and alloys that facilitate heat transfer with minimal resistance. Key materials utilized within this technology include high-performance polymers and innovative metal composites that have been specifically engineered to enhance thermal performance. By incorporating advanced design techniques, Bamhi Thermo ensures that heat is evenly distributed, thereby preventing hotspots and material stress, which can lead to failure or reduced efficiency in thermal systems.

Moreover, the technology utilizes computational modeling and simulation techniques that assist engineers in designing products that maximize thermal performance. These simulations allow for predictive analysis of thermal behavior in real-world applications, ensuring that the solutions are not only theoretical but practically viable.

Applications Across Industries

From automotive to electronics, Bamhi Thermo finds its application in a variety of industries. In the automotive sector, it is used to regulate engine temperatures and improve fuel efficiency. Beyond engine management, Bamhi Thermo plays a vital role in electric vehicles, where efficient thermal management can significantly enhance battery longevity and performance. Electronics manufacturers employ Bamhi Thermo to maintain device performance and longevity by ensuring effective heat dissipation in gadgets and appliances, such as smartphones, laptops, and gaming consoles, where overheating can lead to performance throttling or failure.

- Automotive Industry: In cars, Bamhi Thermo aids in improving combustion efficiency and longevity of components by maintaining optimal engine temperatures even under strenuous conditions. It also plays a critical role in hybrid and electric vehicles where managing battery heat is crucial for safety and performance.

- Electronics and Devices: Gadgets leverage this technology to manage thermal output, thereby enhancing the lifespan and reliability of the product. In high-performance computing, managing heat dissipation is vital to maintain speeds and prevent crashes.

- Industrial Machinery: Machinery and heavy equipment use Bamhi Thermo solutions to maintain operational temperatures, thereby avoiding overheating and breakdowns. Industries such as manufacturing and construction rely on stringent temperature control to ensure safety and efficiency.

- Aerospace: In the aerospace sector, Bamhi Thermo is utilized for thermal protection systems, ensuring spacecraft and satellites can withstand extreme temperature fluctuations during re-entry and operation in diverse environments.

- Renewable Energy: With the rising prominence of solar energy, Bamhi Thermo's technologies are used in photovoltaic systems to optimize energy conversion and heat management, further increasing efficiency in renewable technologies.

Advantages of Bamhi Thermo

The advantages of implementing Bamhi Thermo technology are manifold. Primarily, it allows for greater thermal regulation, which translates to enhanced operational efficiency and reduced energy consumption. Industries can achieve better performance outcomes and a reduced carbon footprint. Additionally, the materials utilized in Bamhi Thermo are often recyclable or derived from sustainable sources, further supporting the global push towards greener technologies.

- Enhanced Efficiency: The ability to maintain controlled temperatures leads to increased efficiency in machine and device operations. Users report enhanced performance metrics and decreased downtime due to thermal-related failures.

- Extended Lifespan: By preventing overheating, Bamhi Thermo extends the operational life of machinery and electronics. This results in lower replacement costs and lower overall lifecycle costs for organizations.

- Environmental Benefits: With reduced energy consumption, there is less environmental impact, aligning industries with sustainability goals. The technology can also support compliance with increasingly demanding environmental regulations.

- Cost-Effectiveness: Despite any initial investment, the savings from reduced energy bills, lower maintenance costs, and fewer component replacements result in a positive return on investment over time.

Comparative Analysis

| Alternative Technologies | Bamhi Thermo Advantages |

|---|---|

| Traditional Heat Sinks | Bamhi Thermo provides superior heat distribution and a reduced footprint. Its lightweight characteristics enable easier integration into devices with strict weight limitations. |

| Liquid Cooling Systems | More reliable with no risk of leakage or additional maintenance requirements. Bamhi Thermo systems do not require pumps or additional components, resulting in lower failure rates. |

| Peltier Modules | Higher efficiency with better scalability across various applications. These systems do not rely on electric power for thermal regulation, thereby reducing energy dependency. |

| Phase Change Materials (PCMs) | Bamhi Thermo provides quicker response times compared to PCMs, which may take time to absorb heat. This responsiveness is crucial in applications requiring immediate thermal regulation. |

Implementation and Considerations

The adoption of Bamhi Thermo technology requires careful consideration of several factors, including the existing infrastructure, budget constraints, and specific industry needs. It is important for businesses to conduct a comprehensive analysis to evaluate the feasibility and potential return on investment when integrating this technology.

Key implementation steps include conducting thermal analysis studies to assess current heat management processes, identifying critical areas where Bamhi Thermo could provide the most significant improvements, and ensuring that personnel are adequately trained in the new technology. Engineers should also evaluate the compatibility of Bamhi Thermo with existing systems and any potential impact on production lines or operational workflows.

Moreover, businesses must consider the regulatory landscape surrounding thermal management technologies, especially if operating within highly regulated industries such as automotive and aerospace. Compliance with safety standards and environmental regulations is paramount, necessitating a thorough understanding of how Bamhi Thermo's systems meet or exceed these requirements.

Case Studies of Successful Implementation

Real-world applications of Bamhi Thermo can best illustrate its effectiveness. One prominent case study involves a leading automotive manufacturer that integrated Bamhi Thermo solutions into their new electric vehicle (EV) line. By doing so, they enhanced battery thermal management, which resulted in an impressive 25% increase in battery life and a 15% improvement in vehicle range due to better thermal control.

Another case study took place in the electronics sector, where a global smartphone maker utilized Bamhi Thermo to manage the thermal output of its high-performance devices. The integration led to a significant reduction in reported thermal throttling issues during high-performance applications, thus improving user experience and customer satisfaction. This shift not only extended product life but also solidified the company's reputation for quality and reliability in a competitive market.

Future Prospects and Innovations

The future for Bamhi Thermo looks promising as industries are continuously searching for ways to enhance energy efficiency and thermal management. With the rise of smart technologies and the Internet of Things (IoT), integrating Bamhi Thermo systems with smart sensors can provide real-time monitoring and adjustments to thermal management. These systems can automatically shift based on operational needs, leading to even greater energy savings and efficiency.

In addition to smart technologies, there are ongoing innovations in materials science, particularly nanotechnology, that show promise for the next generation of thermal management solutions. The development of nanomaterials can lead to even higher conductivity and lower thermal resistance, thus maximizing the efficiency of Bamhi Thermo technology.

Moreover, as industries aim to decarbonize processes, Bamhi Thermo is positioned to play a crucial role in supporting carbon neutrality goals. Technologies that minimize energy waste contribute directly to reducing greenhouse gas emissions and help companies meet regulatory demands for sustainability.

FAQs about Bamhi Thermo

- What industries can benefit from Bamhi Thermo? A wide range of industries, including automotive, electronics, industrial manufacturing and aerospace, can benefit from this technology. Each sector observes distinct advantages related to thermal efficiency and performance.

- How does Bamhi Thermo compare to existing technologies? It offers more efficient heat management and reduced energy consumption compared to traditional methods, with added reliability and safety features that further enhance its appeal.

- Is it cost-effective? While the initial investment might be higher, the savings on energy and maintenance justify the cost. Long-term operational savings often lead to an overall reduction in total cost of ownership.

- Does Bamhi Thermo require special training for implementation? Yes, personnel may need training to understand the new technology, especially in how to operate monitoring tools or adapt existing manufacturing processes to accommodate Bamhi Thermo solutions.

- Can Bamhi Thermo technology be customized for specific needs? Absolutely, Bamhi Thermo solutions are versatile and can be tailored to meet the distinct thermal management requirements of various applications.

Conclusion

In the evolving landscape of industrial technologies, Bamhi Thermo emerges as a notable development within thermal management solutions. Its application across multiple sectors demonstrates its versatility and effectiveness, offering industries a path to enhanced operational efficiency and sustainability. As more industries move toward advanced solutions, Bamhi Thermo stands as a beacon of innovation, advocating for a future where technology harmonizes with environmental and economic goals.

Continued research and development in thermal management technologies will likely propel Bamhi Thermo into new markets, as the demand for energy-efficient and reliable thermal solutions continues to grow. The integration of sustainable practices alongside cutting-edge thermal management technology could redefine industry standards, making Bamhi Thermo not only a leader in thermal management today but a critical player in tomorrow’s technological advancements.