Understanding the Depths of Ckd Scs2

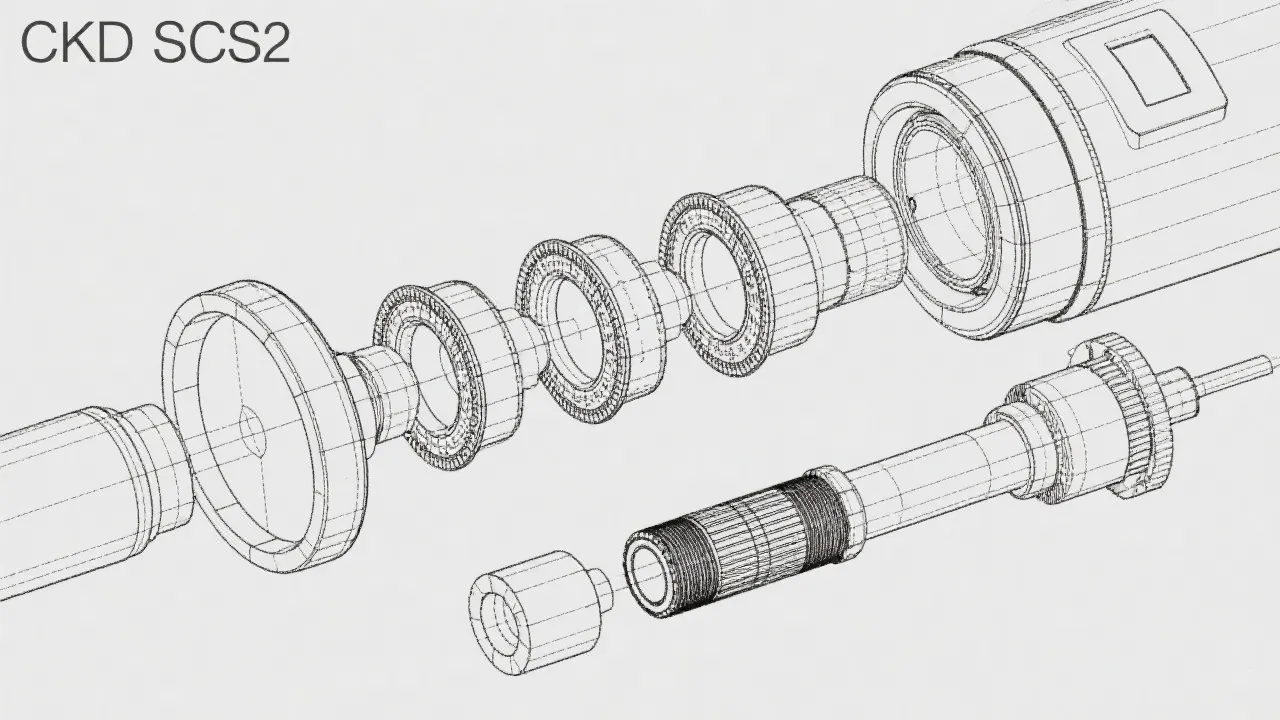

The Ckd Scs2, a key player in the field of pneumatics, is engineered for precision in various industrial applications. Developed by CKD Corporation, the Scs2 series serves to enhance system efficiency and performance. This guide delves into the intricacies of the Ckd Scs2, exploring its functionalities, benefits, and potential applications, and offering readers a technical overview that caters to industry needs.

Introduction to Ckd Scs2

The Ckd Scs2 series represents a shining example of innovation in pneumatic solutions offered by CKD Corporation, a reputable name in the sector. These components are built to drive efficiency and precision, crucial elements in industries ranging from automotive to robotics. The Ckd Scs2 series is designed specifically to meet the increasing demand for streamlined and robust pneumatic systems, aiming to reduce downtime while enhancing performance. With a commitment to quality and innovation, CKD Corporation ensures that each component adheres to high standards within the engineering and manufacturing processes, setting the foundation for reliable operation in diverse applications.

Core Features of Ckd Scs2

The primary feature of the Ckd Scs2 is its adaptability and integration capacity in various systems. Known for their sturdy construction and reliability, these components are essential to maintaining consistency in high-pressure operations. The series also highlights CKD Corporation's commitment to sustainability, with designs that extend component life span and reduce maintenance costs. Furthermore, with their ease of installation and integration, the Ckd Scs2 components significantly cut down setup times, giving businesses more agility in response to technological or market changes. The modular design of the Ckd Scs2 series allows users to construct systems tailored to their specific needs while providing the flexibility to upgrade or reconfigure as operational demands evolve.

Moreover, the Ckd Scs2 components incorporate advanced materials that enhance durability and corrosion resistance, ensuring they can withstand the rigors of industrial applications. The precise manufacturing techniques utilized in the production of these components guarantee high levels of performance, ensuring that they operate efficiently under various conditions. User-friendly interfaces for control and monitoring are also integrated into these systems, allowing operators to easily manage production processes and identify potential issues before they escalate.

Exploring Applications and Benefits

Applications of the Ckd Scs2 range from industrial automation to light manufacturing processes where precision is not just a preference but a necessity. In production lines, the components ensure a synchronized workflow, improving overall equipment efficiency (OEE) metrics. The series also supports high-speed operations, providing smooth and reliable performance while reducing the likelihood of operational errors.

One of the very significant benefits of using the Ckd Scs2 is the reduction in energy consumption, an increasingly critical factor as industries aim to lower their carbon footprints. By optimizing the airflow and enhancing pressure control, these components contribute to more sustainable manufacturing practices. The Ckd Scs2 excels in applications where precise control of force and motion is needed, such as robotic assembly lines, pneumatic conveyors, and automated inspection systems. This contributes not only to energy savings but also leads to a lower total cost of ownership for businesses employing these solutions.

Moreover, the versatility of the Ckd Scs2 series allows it to be utilized in unique applications where specialized features may be required. For example, in the packaging industry, adjustable pressure parameters enable manufacturers to protect delicate contents while optimizing the speed at which products are packaged. Similarly, in the automotive sector, the precise actuation of components is paramount in ensuring the quality and reliability of finished vehicles. The adaptability of these components can lead to significant cost benefits, including a reduction in waste and improved overall productivity.

Step-by-Step System Integration

Implementing the Ckd Scs2 components into existing systems can be efficiently achieved by following these critical steps:

- Requirement Analysis: Assess the existing system to identify the specific needs that the Ckd Scs2 can address. Understanding the operational goals and challenges is vital for effective integration.

- Component Selection: Choose the correct model and specification of the Ckd Scs2 that aligns with your operational goals. CKD Corporation offers a diverse range of options to accommodate various pressure, flow, and application requirements.

- System Preparations: Prepare the systems for integration, ensuring compatibility and alignment with the new components. This may involve necessary upgrades to existing systems to support enhanced functionality.

- Installation: Carefully install Ckd Scs2 components, following the manufacturer’s guidelines to avoid any operational issues. Proper installation is critical for maximizing performance and reliability.

- Testing and Adjustment: Conduct thorough testing to ensure that all systems operate to capacity, making adjustments as necessary. Monitoring performance metrics will help in understanding the effectiveness of the integration.

In addition, documenting the integration process can be beneficial for future maintenance and if further expansion or modifications to the system are required. Building a knowledge base around the usage of Ckd Scs2 components enhances the skill set of the workforce and contributes to the overall efficiency of operations.

Comparison with Competing Products

| Feature | Ckd Scs2 | Competitor A | Competitor B |

|---|---|---|---|

| Durability | High | Moderate | High |

| Energy Efficiency | Excellent | Good | Moderate |

| Price | Competitive | Cheaper | Premium |

| Ease of Integration | Seamless | Challenging | Moderate |

While Ckd Scs2 components stand out for their durability and energy efficiency, it is essential to consider the overall value when comparing them to competing products. The competitive pricing of the Ckd Scs2 ensures that customers receive exceptional quality without a prohibitive cost. Furthermore, the ease of integration provided by these components minimizes the downtime typically associated with implementing new systems, allowing businesses to maintain their operational rhythm. It’s this combination of quality, efficiency, and value that makes the Ckd Scs2 a preferred choice in many industries.

Maintaining Your Ckd Scs2

To ensure longevity and maintain peak operational performance of the Ckd Scs2, regular maintenance is crucial. Keeping components clean and free from debris will prevent premature wear. Scheduled inspections should be performed by qualified personnel to ensure all parts remain in excellent working order. Additionally, updating the control software when necessary ensures that the system remains compatible with evolving technological standards, securing your investment's future. Regular maintenance not only prolongs the lifespan of the components but also facilitates continuous optimization of system performance.

Establishing a routine maintenance schedule allows for identifying potential issues that could lead to more significant problems down the road. Many organizations incorporate predictive maintenance techniques powered by real-time data analytics, which can foresee operational inefficiencies or failures. By leveraging these insights, operators can strive for corrective measures before an issue disrupts productivity.

Moreover, it is recommended to train operators and maintenance staff on the specific features and operational characteristics of the Ckd Scs2. Developing a strong knowledge-sharing culture within the organization decreases the likelihood of prolonged problem-solving during operational challenges and promotes a proactive approach to maintenance.

FAQs

- What industries benefit very from Ckd Scs2? Industries such as automotive manufacturing, robotics, electronics, and food packaging benefit greatly from the precision and efficiency offered by the Ckd Scs2. The series is especially valuable in sectors where precise motion control and reliability are critical to meeting production demands.

- How does Ckd Scs2 improve system performance? By providing high pressure control and energy-efficient operation, the Ckd Scs2 minimizes system downtime and enhances the productivity of manufacturing processes. The integration of these components can lead to significant gains in overall output and quality, making them an invaluable asset to modern industrial setups.

- Can the Ckd Scs2 be customized for unique applications? Yes, CKD Corporation provides options to customize components within the Ckd Scs2 series to meet specific operational needs. Customization options help organizations to tailor functionality according to unique process requirements without compromising on performance or reliability.

- What support services does CKD Corporation offer with the Ckd Scs2? CKD Corporation provides a range of support services, including technical assistance, training programs, and access to extensive resources that ensure users can maximize the potential of the Ckd Scs2 components. These services are designed to enhance user experience and promote effective operational practices.

- How does the Ckd Scs2 contribute to environmental sustainability? The Ckd Scs2 series is designed to optimize energy consumption, reducing waste and emissions in manufacturing processes. By improving pressure management and airflow, these components not only enhance performance but also align with corporate sustainability goals.

The Ckd Scs2 is a superior choice for those looking to enhance pneumatic systems' efficiency and reliability. Its applications span across various demanding industries, setting a high benchmark for excellence in system performance and sustainability. Investing in Ckd Scs2 components not only addresses immediate operational needs but also positions businesses to take advantage of future advancements in pneumatic technology.

As industries continue to evolve and the demand for efficiency and sustainability grows ever more critical, the Ckd Scs2 series stands at the forefront of pneumatic innovation. Businesses considering this series will find that not only do these components meet contemporary performance standards, but they also pave the way for future-ready operations capable of adapting to ever-changing market landscapes.

In conclusion, the Ckd Scs2 embodies a holistic approach to pneumatic engineering, merging cutting-edge technology with practical efficiency. Companies seeking to streamline operations, enhance productivity, and reduce costs will undeniably recognize the value offered by Ckd Scs2 components. By making this integration, organizations can ensure that they remain competitive, profitable, and environmentally responsible in an evolving industrial landscape.

Ultimately, as businesses aim to drive growth and success in their respective fields, the incorporation of advanced pneumatic systems like the Ckd Scs2 can play a pivotal role in achieving those aspirations. By embracing innovation and efficiency, organizations are equipped to overcome challenges, remain agile, and stand resilient amid market fluctuations.