Understanding Corelite Dwi in Engineering

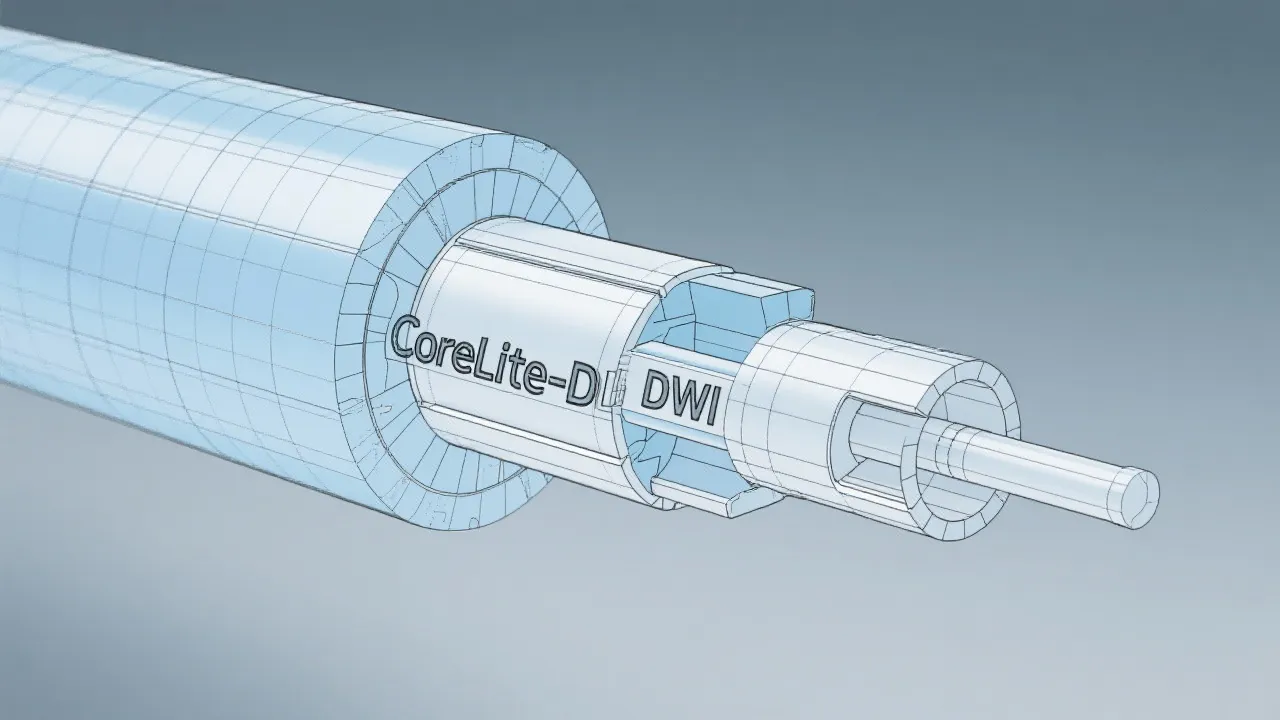

Corelite Dwi is a significant component in various engineering and construction projects, known for its durability and efficiency. This article delves into the technical aspects and applications of Corelite Dwi, providing insights into its role and benefits in modern infrastructure. Engineers and industry leaders have increasingly leveraged Corelite Dwi for its robust performance and cost-effectiveness.

Overview of Corelite Dwi in Engineering

Corelite Dwi has emerged as a critical material in the fields of engineering and construction. Renowned for its strength and efficiency, Corelite Dwi is utilized in multiple applications, ranging from structural components to complex infrastructure projects. Its unique properties make it indispensable for engineers aiming to achieve optimal durability and functionality in their constructions. The evolution of this material reflects the rapid advances in engineering science, as it incorporates cutting-edge research into practical applications that improve both performance and sustainability.

The rise of Corelite Dwi can be attributed to the pressing need for materials that not only fulfill structural requirements but also meet environmental standards. As global construction practices shift towards more sustainable methodologies, the relevance of Corelite Dwi grows. This adaptability ensures that engineers can leverage its benefits while adhering to stringent regulatory frameworks that demand environmentally conscious practices.

The Properties and Benefits of Corelite Dwi

Corelite Dwi is distinguished by its high strength-to-weight ratio, making it exceptional for projects where both strength and ease of handling are paramount. It offers resistance to various environmental factors, including moisture and temperature fluctuations, which enhances the longevity of structures where it is employed. Additionally, its adaptability across different engineering uses further underscores its value. Corelite Dwi exhibits exceptional mechanical properties, including tensile strength, compressive strength, and shear strength, enabling its use in highly stressed applications.

In contrast to conventional materials such as steel or concrete, Corelite Dwi provides improved performance under extreme conditions. For instance, in situations where thermal expansion and contraction could lead to structural failure, Corelite Dwi maintains its integrity thanks to its stable dimensional properties. Engineers find this characteristic particularly advantageous when designing buildings or structures that will be subjected to severe temperature variations.

Furthermore, the manufacturing process of Corelite Dwi has been optimized to reduce waste and energy consumption, aligning with modern sustainability goals. For engineers prioritizing budget management, this material provides a feasible solution without compromising on quality or performance. The reduced maintenance needs associated with Corelite Dwi translate into good economic benefits for project stakeholders. In essence, the long-term performance of Corelite Dwi can lead to significant lifecycle cost savings, further reinforcing its appeal in engineering applications.

Applications of Corelite Dwi

The versatility of Corelite Dwi allows it to be integrated into a myriad of engineering projects. From bridge construction to aerospace components, its applications are diverse and expansive. The stability and reliability of Corelite Dwi support its use in demanding environments, enhancing the overall resilience of infrastructure. Its exceptional abilities allow it to withstand dynamic loads, making it suitable for applications in which structural integrity is vital.

In civil engineering, Corelite Dwi has been prominently featured in the construction of not only bridges but also high-rise buildings, where its strength allows for slender yet stable framework designs. With urban spaces increasingly prioritizing efficiency in their designs, the use of Corelite Dwi contributes to more sustainable city planning by reducing material usage without sacrificing safety and durability.

In the aerospace sector, Corelite Dwi's lightweight characteristics play a fundamental role in enhancing aircraft performance. This improvement is crucial as the aerospace industry continually seeks to optimize operational efficiency while reducing fuel consumption. By employing Corelite Dwi, engineers can develop aircraft that meet stricter emissions standards and reduce their carbon footprints significantly.

In addition to aerospace and civil applications, Corelite Dwi finds a place in the marine industry, where it supports marine structures in withstanding harsh environmental conditions. This application is vital, as marine infrastructures are subjected to corrosive environments and require materials that can endure prolonged exposure to water, salt, and temperature changes.

| Application Area | Description |

|---|---|

| Bridge Construction | Utilization in bridges for weight reduction and increased load capacity, enhancing overall structural efficiency. |

| Aerospace Engineering | Improves aircraft efficiency through reduced structural weight while maintaining safety and performance standards. |

| Marine Engineering | Supports marine structures in withstanding harsh environmental conditions, extending the service life of marine installations. |

| Building Construction | Employed in the development of high-rise buildings where reducing material weight contributes to improved seismic performance. |

| Renewable Energy | Used in wind turbine construction where light and sturdy materials are essential for efficiency and effectiveness. |

Case Studies and Real-World Implementations

Several real-world applications highlight the advantages of Corelite Dwi. In structural engineering, it has been used in the construction of bridges, where its low weight and high strength significantly reduce loads on supporting structures. A prime example is the construction of the Smith River Bridge, which utilizes Corelite Dwi to achieve a lighter design that enhances its resilience against environmental stresses while simplifying its assembly process. Engineering teams reported that the integration of Corelite Dwi allowed for smaller foundations, thereby reducing the overall project cost and time required for completion.

Additionally, the aerospace sector benefits from its lightweight characteristics, improving fuel efficiency and safety. The recent development of a lightweight aircraft fuselage made from Corelite Dwi showcases the material's performance attributes. Test flights demonstrated not only improved fuel consumption but also enhanced flight stability due to the material's robust properties. With rising fuel prices and tighter regulations on emissions in the aviation market, such advancements are critical for manufacturers looking to maintain a competitive edge.

In the realm of marine engineering, Corelite Dwi has proven its worth by enhancing the performance of offshore installations. For instance, numerous offshore platforms have incorporated Corelite Dwi in their structural designs. These platforms face extreme weather conditions, including harsh waves and corrosive saltwater. By utilizing Corelite Dwi, engineers have succeeded in extending the operational life of these platforms, significantly reducing maintenance costs and ensuring safety in offshore operations.

Moreover, in building construction, multiple high-rise skyscrapers have begun using Corelite Dwi for curtain wall systems, which not only improves the building's aesthetic appeal but also contributes to its structural performance. This application minimizes the weight burden while optimizing energy efficiency through better thermal insulation properties.

Industry Expert Insights on Corelite Dwi

Industry experts highlight the growing preference for Corelite Dwi across engineering disciplines due to its comprehensive benefits. The material's contribution to sustainable construction practices is particularly noteworthy, as it aligns with global efforts to diminish the environmental impact of engineering activities. Many renowned structural engineers emphasize that the shift to lighter materials such as Corelite Dwi symbolizes a new era in construction methods, where efficiency and sustainability coexist harmoniously.

Experts discuss how Corelite Dwi enables engineers to break away from the constraints imposed by traditional materials, allowing for innovative designs that were previously unattainable. They foresee a future where Corelite Dwi could become a standard material in not just engineering, but in multiple sectors, such as automotive and consumer goods, where lightweight and durable materials are essential.

Moreover, the integration of advanced manufacturing techniques, such as 3D printing with Corelite Dwi, could unlock even more design possibilities and applications. Experts are currently exploring these methodologies to create complex geometries that traditional fabrication processes cannot achieve. One research group has reported successful prototypes that utilize Corelite Dwi to form both structural and decorative elements in architecture, thus showcasing its versatility and adaptability.

Future Prospects of Corelite Dwi

Looking ahead, Corelite Dwi is poised to play an integral role in the future of engineering and construction. As innovations in material science continue to develop, the properties and applications of Corelite Dwi are expected to expand, offering novel solutions to engineering challenges. Researchers are currently exploring its potential in smart infrastructure and environmentally adaptive designs. The advent of smart materials, which respond to their environment, may further enhance the capabilities of Corelite Dwi in building applications, allowing structures to adjust dynamically to changes in temperature, humidity, or stress levels.

Additionally, the potential incorporation of Corelite Dwi in renewable energy applications, such as solar panels and wind turbine blades, presents exciting opportunities. Its lightweight and durable properties align perfectly with the needs of these technologies, where reducing weight can enhance efficiency and energy output. As the world increasingly embraces renewable energy sources, materials like Corelite Dwi will become vital in the engineering of next-generation energy solutions.

The construction industry’s shift toward prefabrication and modular designs also points to a promising future for Corelite Dwi. Prefabricated elements utilizing this material can be manufactured offsite and assembled with reduced labor on construction sites, leading to significant time savings and cost reductions. As demand for quick, efficient building methods grows, Corelite Dwi's role in these processes will likely become even more pronounced.

FAQs

- What makes Corelite Dwi preferable over other materials? Corelite Dwi's strength, light weight, and environmental resistance make it an optimal choice for a variety of engineering applications, surpassing many traditional materials in these aspects.

- Are there any limitations to using Corelite Dwi? While its benefits are vast, Corelite Dwi's applications may be constrained by initial costs compared to some traditional materials, though these are often offset by good savings over time.

- How is Corelite Dwi contributing to sustainable engineering practices? Its durability and reduced maintenance requirements contribute significantly to sustainability efforts by increasing the lifecycle of structures and minimizing resource consumption.

- Can Corelite Dwi be recycled or reused? Yes, Corelite Dwi can be recycled, and its efficient manufacturing process allows for reusing waste materials, thus promoting a circular economy.

- What future innovations are being explored with Corelite Dwi? Researchers are currently investigating the integration of Corelite Dwi with smart technologies and renewable energy applications, alongside advances in manufacturing processes like 3D printing.