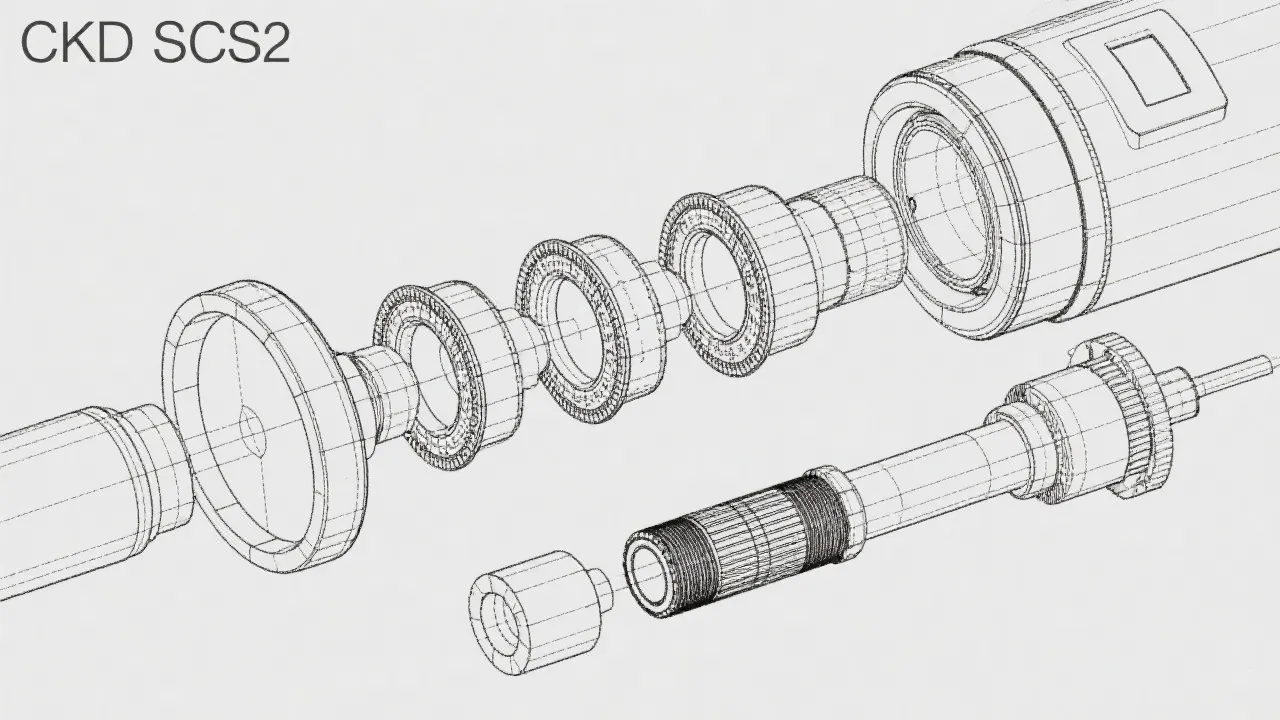

Understanding Ckd Scs2 in Detail

This article delves into Ckd Scs2, a critical component in various industrial applications. Aimed at both scholars and industry professionals, it explores the technical aspects, uses, and significance of Ckd Scs2. The analysis covers its impact on efficiency and operations, alongside a detailed FAQ for commonly asked questions, providing a comprehensive understanding for readers.

Introduction to Ckd Scs2

Ckd Scs2 has emerged as a pivotal element in industrial engineering and manufacturing processes. It represents a blend of intricate technologies that facilitate operations across various sectors. The tool is known for its ability to improve efficiency and precision in manufacturing environments. This article provides an expert analysis of its components, applications, and the potential advantages of integrating Ckd Scs2 into industrial operations.

Defining Ckd Scs2

As a sophisticated assembly within the manufacturing sector, Ckd Scs2 serves a critical role in enhancing machinery capability. Originally developed in response to a growing need for precise control systems, it integrates seamlessly into the assembly line, providing operational efficiencies that were previously difficult to achieve. Its robust nature allows it to function in diverse environments, contributing significantly to productivity improvements.

The technology behind Ckd Scs2 is not just a single standalone process but is a complex amalgamation of software and hardware that calibrates machinery with pinpoint accuracy. This dual approach enables real-time adjustments to variables, ensuring that production lines adapt dynamically to the flow of incoming data and changing operational conditions. For instance, software algorithms continuously monitor key performance metrics, and upon detecting any deviation from predefined thresholds, the hardware component instantaneously adjusts the machines’ functioning to re-align operations.

Applications of Ckd Scs2

The versatility of Ckd Scs2 makes it suitable for a wide array of applications across different industries. From automotive to pharmaceutical manufacturing, its ability to automate control processes ensures that manufacturers can maintain high standards of production while reducing manual errors. Here are some key applications:

- Automotive Industry: In this sector, Ckd Scs2 ensures precise control of assembly lines, enhancing the accuracy and efficiency of automotive parts production. The integration helps in streamlining operations like welding, painting, and quality checking, where timing and precision are critical.

- Pharmaceutical Manufacturing: Its ability to maintain stringent control standards is crucial in producing pharmaceuticals with consistent quality. The technology assists in the regulation of both raw materials and finished products, ensuring compliance with health regulations and safety standards. This is particularly important since any deviation can have serious implications for public health.

- Electronics Assembly: By automating processes, it reduces errors and increases the speed of assembly for complex electronic components. This application is vital, given the intricate nature and miniaturization of modern electronic devices, where even a minute error can lead to failures in functionality.

- Food and Beverage Production: Ckd Scs2 can manage bulk processing and packaging, ensuring optimal flow rates and product quality. In this industry, precise temperature control and monitoring are essential to maintain freshness and prevent spoilage.

- Textile Manufacturing: In textile factories, Ckd Scs2 facilitates automated weaving and dyeing processes, allowing for rapid production cycles while maintaining color consistency and fabric integrity.

Benefits of Using Ckd Scs2

The implementation of Ckd Scs2 offers numerous benefits, many of which are pivotal for modern industrial settings:

- Enhanced Efficiency: By automating and optimizing control processes, it significantly boosts operational efficiency. This increased efficiency often translates into lower energy consumption, as operations become more streamlined.

- Cost Reduction: With less dependency on manual labor, companies can reduce labor costs while minimizing human error-related expenses. This factor is especially crucial in sectors characterized by tight profit margins where every cost-saving measure contributes to overall financial health.

- Improved Precision: Its precise control helps maintain high-quality standards, vital for sectors where precision is paramount. Enhanced control of manufacturing processes means fewer defects, which leads to lower warranty claims and customer dissatisfaction.

- Real-Time Monitoring: The capability of Ckd Scs2 systems to monitor processes in real-time allows for immediate corrective actions when deviations occur, avoiding costly downtimes.

- Flexibility and Adaptability: Ckd Scs2 systems can be easily adapted to changes in product designs or production volumes, giving manufacturers the agility needed to respond to market demands quickly.

- Data Collection and Analysis: The integration of advanced data analytics with Ckd Scs2 systems enables manufacturers to gather insights into their operations, driving continuous improvement initiatives across their processes.

Challenges in Implementing Ckd Scs2

Despite the significant advantages, there are challenges associated with the implementation of Ckd Scs2:

- Initial Setup Costs: The high initial investment can be a barrier for some companies. Organizations need to consider not only the purchase price of Ckd Scs2 systems but also the associated costs of integration and maintenance.

- Training Requirements: Employees need specialized training to effectively operate the systems, requiring additional time and resources. It’s essential for companies to develop comprehensive training programs to ensure their staff can utilize the technology efficiently.

- Integration Issues: Integrating new technologies with existing systems can be complex and may require customized solutions. Businesses often face data compatibility issues or the need for legacy system upgrades, which can complicate seamless operation.

- Change Management: Shifting to systems like Ckd Scs2 often necessitates a cultural change within the organization. Resistance from employees accustomed to legacy systems can hinder the adoption of new processes.

Industry Perspectives

From an industry standpoint, the adoption of Ckd Scs2 is a forward-thinking move that aligns with trends toward automation and digitalization. Experts suggest that as the industrial landscape continues evolving, the reliance on such advanced systems will only increase, driving innovation and setting new benchmarks in manufacturing efficiencies. The global shift towards Industry 4.0, which incorporates internet of things (IoT) technologies and advanced analytics, is a clear indication of the future direction of manufacturing sectors worldwide.

Furthermore, the recent global challenges, including supply chain disruptions due to the pandemic, have heightened the necessity for robust, versatile manufacturing solutions that Ckd Scs2 provides. Companies are increasingly aware that technological investments directly correlate with their resilience and adaptability in facing turbulent market conditions.

As industries move toward more sustainable practices, Ckd Scs2 technologies present opportunities for reducing waste and enhancing energy efficiency. Manufacturers are now tasked with not only enhancing productivity but also minimizing their ecological footprint. This dual objective creates a fertile ground for innovations and practices that accommodate both economic and environmental considerations.

| Feature | Benefits |

|---|---|

| Automation Control | Automates complex processes, reducing labor costs and increasing output. |

| Precision Engineering | Enhances precision in production, improving product quality and consistency. |

| Scalability | Offers scalable solutions suitable for various industry sizes and types. |

| Real-Time Feedback | Provides instant feedback on production processes, enabling quick response times. |

| Cross-Platform Integration | Compatible with a range of existing technologies for seamless operations. |

FAQs

What industries benefit very much from Ckd Scs2?

Industries including automotive, pharmaceuticals, electronics, food and beverage, and textiles see significant benefits due to the precision and efficiency improvements provided by Ckd Scs2. The technology’s capacity for error reduction and enhanced productivity is instrumental in these sectors where consistent output quality is essential.

Is there a steep learning curve associated with Ckd Scs2?

While there is an initial learning period involved, most companies find the good benefits far outweigh the initial investment in training. Organizations that invest in a sound change management strategy coupled with effective training programs tend to experience smoother transitions and quicker adaptations to Ckd Scs2 implementations.

How does Ckd Scs2 impact operational costs?

Although initial setup may be costly, ongoing operational costs typically decrease due to improved efficiencies and reduced manual labor requirements. Enhanced automation limits human error and results in fewer defects, translating to lower costs in warranty claims and customer complaints.

How does Ckd Scs2 contribute to sustainable manufacturing practices?

Ckd Scs2 contributes to sustainability by optimizing resource usage and reducing waste production. Its precise controls help minimize excess material consumption and waste generation, aligning with broader environmental goals while enhancing productivity.

Is Ckd Scs2 customizable for specific processes?

Yes, Ckd Scs2 can be tailored to meet specific industry needs and production processes, enabling businesses to design a system that fits their operational requirements without compromising efficiency or effectiveness.

Conclusion

In conclusion, Ckd Scs2 is more than just a technological advancement; it represents a step change in how industries operate with automation and efficiency. By embracing this system, companies can position themselves at the forefront of manufacturing excellence, harnessing the technology to drive forward both productivity and quality standards. The ongoing evolution of Ckd Scs2’s capabilities further promises to enhance operational frameworks, making it a pivotal system in shaping the future of industrial manufacturing.

As Ckd Scs2 continues to evolve, further innovations will likely emerge. This could include integrations with artificial intelligence and machine learning, allowing systems to become smarter and more autonomous in their decision-making processes. The potential for predictive maintenance and operational analytics powered by Ckd Scs2 could usher in a new era of manufacturing efficiency, making it an essential component in the toolbox of any modern manufacturer seeking to remain competitive in a rapidly changing marketplace.